Service Manual and Parts List Manual Toshiba e-STUDIO 2040C/2540C/3040C/3540C/4540C (Version 05 F, Oct. 2013);

This manual is in the PDF format and have detailed Diagrams, pictures and full procedures to diagnose and repair your Toshiba e-STUDIO copier.

You can print, zoom or read any diagram, picture or page from this Service Manual and Parts List Manual. Every chapter on this manual is fully detailed and contain all the simulation codes, trouble codes, maintenance procedures, reset procedures, diagnose procedures of Toshiba e-STUDIO 2040C/2540C/3040C/3540C/4540C photocopier. You can find easily everything what do you need.

To see what contain, please read table of contents:

So, if your device is not rooted then root it first.Whenever we hear about an app, the first thing we do is find it on Google Play Store. You will get plenty of results of it but few of them does not work. But this app is not available there, so you might have searched it on google. Download game killer full for android.

Download Mendeley Desktop for Linux. Download for generic Linux. Download for Ubuntu and Kubuntu 16.04 LTS, 17.04 and Debian Stretch 9. See release notes. Other systems: Mendeley Desktop for Windows Mendeley Desktop for macOS. New Mendeley Reference Manager is now available Get started. Download Mendeley Desktop for macOS. Download Mendeley Desktop for macOS. MacOS 10.10 (Yosemite), 10.11 (El Capitan), 10.12 (Sierra), 10.13 (High Sierra) See release notes. Other systems: Mendeley Desktop for Windows Mendeley Desktop for Linux. New Mendeley Reference Manager is now available Get started. https://kitsclever117.weebly.com/download-mendeley-115-mac-os.html. Mendeley Desktop is a reliable macOS application that makes it easy for you to manage, share and discover research papers. Moreover, Mendeley Desktop also provides access to an online social network specially made for researchers, where you can share and find research data with ease.

- Toshiba E Studio 2040c User Manual Free

- Toshiba 2040c Manual

- Toshiba 2040c Brochure

- Toshiba E Studio 3040c

Content for Service Manual:

1. FEATURE

1.1 Main Feature of e-STUDIO2040C/2540C/3040C/3540C/4540C

2. SPECIFICATIONS/ACCESSORIES/OPTIONS/SUPPLIES

2.1 Specifications

2.1.1 General

2.1.2 Copy

2.1.3 Print

2.1.4 Scan

2.1.5 e-Filing

2.1.6 Internet Fax

2.1.7 Network Fax

2.2 Accessories

2.3 System List

2.4 Supplies

3. OUTLINE OF THE MACHINE

3.1 Sectional View

3.1.1 Front side-1

3.1.2 Front side-2

3.1.3 Rear side

3.2 Electric Parts Layout

3.3 Symbols and Functions of Various Components

3.3.1 Motors

3.3.2 Sensors and switches

3.3.3 Electromagnetic spring clutches

3.3.4 Solenoids

3.3.5 PC boards

3.3.6 Lamps and heaters

3.3.7 Thermistors, thermopiles, and thermostats

3.3.8 Transformer

3.3.9 Others

3.4 Copy Process

3.5 Comparison with e-STUDIO2020C/2330C/2820C/2830C/3520C/3530C/4520C

3.6 General Operation

3.6.1 Overview of Operation

3.6.2 Description of Operation

3.6.3 Detection of Abnormality

3.7 Control Panel

3.7.1 General Description

3.7.2 Description of Operation

3.8 Scanner

3.8.1 General Description

3.8.2 Construction

3.8.3 Functions

3.8.4 Description of Operation

3.8.5 Process of detection of original size

3.9 Laser Optical Unit

3.9.1 General Description

3.9.2 Laser Precautions

3.10 Paper Feeding System

3.10.1 General Descriptions

3.10.2 Composition

3.10.3 Functions

3.10.4 Description of Operation

3.11 Process Unit Related Section

3.11.1 General description

3.11.2 Composition

3.11.3 Functions

3.11.4 Drum driving sleep mode

3.11.5 Description of Operation

3.12 Developer Unit

3.12.1 General Description

3.12.2 Composition

3.12.3 Functions

3.12.4 Functions of the toner cartridge PC board (CTRG)

3.13 Transfer Unit

3.13.1 General Descriptions

3.13.2 Composition

3.13.3 Difference of transfer belt unit

3.13.4 Contacting and releasing movement of the 2nd transfer roller

3.14 Image Quality Control

3.14.1 General Description

3.15 Fuser unit / Paper exit section

3.15.1 General Description

3.15.2 Composition

3.15.3 Difference of fuser unit

3.15.4 Electric Circuit Description

3.16 Automatic Duplexing Unit (ADU)

3.16.1 General Description

3.16.2 Composition

3.16.3 Drive of ADU

3.16.4 Description of Operations

3.17 Power Supply Unit

3.17.1 General description

3.17.2 Functions

3.17.3 Operation of DC Output Circuits

3.17.4 Output Channel

3.17.5 Fuse

4. DISASSEMBLY AND REPLACEMENT

4.1 Covers

4.1.1 Front cover

4.1.2 Inner tray

4.1.3 Tray back cover

4.1.4 Front upper cover

4.1.5 Front right cover

4.1.6 Left upper cover

4.1.7 Left cover

4.1.8 Left lower cover

4.1.9 Left rear cover

4.1.10 Right upper cover

4.1.11 Right rear cover

4.1.12 Right rear hinge cover

4.1.13 Right lower cover

4.1.14 Right front hinge cover

4.1.15 Bypass rear cover

4.1.16 Right inner cover

4.1.17 Upper rear cover

4.1.18 Rear cover-1

4.1.19 Rear cover-2

4.1.20 Rear cover-3

4.1.21 Waste toner cover

4.2 Control Panel

4.2.1 Stopper

4.2.2 Control panel unit

4.2.3 DSP board

4.2.4 KEY board

4.2.5 Touch panel (TCP)

4.2.6 Control panel cover

4.3 Scanner

4.3.1 Original glass

4.3.2 Lens cover

4.3.3 Automatic original detection sensor (APS sensor)

4.3.4 Exposure lamp (EXP)

4.3.5 Lens unit

4.3.6 Scan motor (M1)

4.3.7 Carriage-1

4.3.8 Inverter board (INV)

4.3.9 Carriage wire / carriage-2

4.3.10 Carriage home position sensor (S6)

4.3.11 Platen sensor (S7)

4.3.12 SLG board (SLG)

4.3.13 Scanner unit cooling fan (M30)

4.3.14 Exposure lamp cooling fan (M32)

4.4 Laser Optical Unit

4.4.1 Laser optical unit

4.4.2 Shutter unit

4.4.3 Shutter motor (M12)

4.4.4 Shutter status detection sensor (S20)

4.4.5 Slit glass cleaning pad

4.4.6 Polygonal motor

4.5 Paper Feeding System

4.5.1 Bypass unit

4.5.2 Hinge assembly

4.5.3 SFB board (SFB)

4.5.4 Bypass feed upper cover

4.5.5 Bypass upper guide

4.5.6 Bypass pickup solenoid (SOL1)

4.5.7 Bypass paper sensor (S40)

4.5.8 Bypass pickup roller

4.5.9 Bypass feed roller

4.5.10 Bypass transport roller

4.5.11 Bypass feed clutch (CLT8)

4.5.12 Bypass separation roller

4.5.13 Bypass feed sensor (S41)

4.5.14 Drawer feeding unit

4.5.15 Tray-up sensor (S31/S35) / Empty sensor (S32/S36)

4.5.16 Paper stock sensor (S33/S37)

4.5.17 Separation roller

4.5.18 Feed roller

4.5.19 Pickup roller

4.5.20 Drawer feed clutch (CLT3/CLT6)

4.5.21 Tray-up motor (M21)

4.5.22 Tray drive unit

4.5.23 2nd drawer transport clutch (Low speed) (CLT4)

4.5.24 2nd drawer transport clutch (High speed) (CLT5)

4.5.25 1st drawer detection switch (SW5) / 2nd drawer detection switch (SW6)

4.5.26 Paper feed guide assembly

4.5.27 2nd drawer feed sensor (S34)

4.5.28 Side cover switch (SW4)

4.5.29 Registration guide

4.5.30 Registration sensor (S28)

4.5.31 1st drawer feed sensor (S30)

4.5.32 Registration roller (Rubber)

4.5.33 Registration motor unit

4.5.34 Registration motor (M19)

4.5.35 Registration roller (Metal)

4.5.36 Paper dust holder

4.5.37 1st drawer transport clutch (Low speed) (CLT2)

4.5.38 Feed/transport motor (M20)

4.5.39 Feed/transport gear unit

4.5.40 1st drawer transport clutch (High speed) (CLT1)

4.5.41 1st drawer transport roller

4.5.42 2nd drawer transport roller

4.6 Process Unit Related Section

4.6.1 Process unit (EPU)

4.6.2 Process cover

4.6.3 Cleaning unit/ Developer unit

4.6.4 Main charger assembly

4.6.5 Main charger cleaner

4.6.6 Main charger grid

4.6.7 Needle electrode

4.6.8 Drum

4.6.9 Drum cleaning blade

4.6.10 Drum thermistor (THM1, THM2)

4.6.11 Discharge LED (ERS-Y, ERS-M, ERS-C, ERS-K)

4.6.12 Needle electrode cleaner detection sensor (S21)

4.6.13 Drum drive unit

4.6.14 Drum motor (M10)

4.6.15 Drum switching motor (M11)

4.6.16 Drum switching detection sensor (S19)

4.6.17 K drum phase sensor (S44)

4.6.18 Color drum phase sensor (S43)

4.7 Developer Unit

4.7.1 Waste toner box

4.7.2 Developer filter

4.7.3 Developer material

4.7.4 Doctor blade

4.7.5 Auto-toner sensor (S22, S23, S24, S25)

4.7.6 Developer sleeve

4.7.7 Mixer

4.7.8 Waste toner transport motor (M31)

4.7.9 Temperature / humidity sensor (S12)

4.7.10 Waste toner box full detection sensor (S13)

4.7.11 Waste toner paddle motor lock detection sensor (S14)

4.7.12 Waste toner paddle motor (M6)

4.7.13 Waste toner transport unit

4.7.14 Waste toner cover open/close detection switch (SW8)

4.7.15 Auger lock detection sensor (S42)

4.7.16 Developer unit motor (M9)

4.7.17 Developer drive unit

4.7.18 Toner motor assembly

4.7.19 Toner motor (M2, M3, M4, M5)

4.7.20 Toner cartridge detection sensor (S8, S9, S10, S11)

4.7.21 Ozone filter-1

4.7.22 EPU cooling fan (M33)

4.7.23 Ozone exhaust fan (M24)

4.7.24 Internal cooling fan (M23)

4.7.25 Ozone filter-2

4.7.26 Ozone filter-3

4.7.27 Front cover opening/closing switch (SW10)

4.8 Transfer Unit

4.8.1 Transfer belt cleaning unit

4.8.2 Transfer belt cleaning blade / Blade seal

4.8.3 Transfer belt unit (TBU)

4.8.4 Transfer belt

4.8.5 Drive roller

4.8.6 1st transfer roller

4.8.7 2nd transfer facing roller / 2nd transfer facing roller cleaning film

4.8.8 Tension roller

4.8.9 1st transfer roller cam motor (M8)

4.8.10 1st transfer roller status detection sensor (S15)

4.8.11 2nd transfer unit (TRU)

4.8.12 2nd transfer roller

4.8.13 TRU cover

4.8.14 Paper clinging detection sensor (S27)

4.8.15 2nd transfer roller position detection sensor (S29)

4.8.16 Transfer belt motor unit

4.8.17 Transfer cover switch (SW3)

4.9 Image Quality Control

4.9.1 Image quality control unit

4.9.2 Image position aligning sensor (front) (S16)

4.9.3 Image position aligning sensor (rear) (S17)

4.9.4 Image quality sensor (S18)

4.9.5 Sensor shutter solenoid (SOL2)

4.10 Fuser unit / Paper Exit Section

4.10.1 Fuser unit

4.10.2 Front side cover

4.10.3 Rear side cover

4.10.4 Heat roller cover

4.10.5 Pressure roller cover

4.10.6 Transport guide

4.10.7 Separation finger unit / Separation finger

4.10.8 Pressure roller / Pressure roller lamp (LAMP3)

4.10.9 Separation plate / Fuser belt unit / Heater lamp (center / side / sub)

4.10.10 Fuser belt / Heat roller / Fuser belt guide / Fuser roller

4.10.11 Pressure roller thermostat (THMO3)

4.10.12 Pressure roller center thermistor (THM4) / Pressure roller rear thermistor

(THM5)

4.10.13 Fuser belt center thermostat (THMO1)

4.10.14 Fuser belt rear thermostat (THMO2)

4.10.15 Fuser belt front thermistor (THM3)

4.10.16 Exit sensor (S26)

4.10.17 Exit unit

4.10.18 Upper exit roller / Lower exit roller

4.10.19 Fuser belt center thermopile(THMP1) / Fuser belt rear thermopile(THMP2). 4-160

4.10.20 Fuser motor (M17)

4.10.21 Exit section drive unit

4.10.22 Fuser drive unit

4.10.23 Fuser/exit section cooling fan (M25) / Exit motor (M18)

4.11 Automatic Duplexing Unit (ADU)

4.11.1 ADU maintenance position

4.11.2 Automatic Duplexing Unit (ADU)

4.11.3 ADU inside rear cover

4.11.4 ADU opening/closing switch (SW7)

4.11.5 ADU board (ADU)

4.11.6 ADU cover

4.11.7 Paper guide

4.11.8 ADU clutch (CLT7)

4.11.9 ADU drive unit / ADU motor (M22)

4.11.10 Upper transport roller

4.11.11 Middle transport roller

4.11.12 Lower transport roller

4.11.13 ADU entrance sensor (S38)

4.11.14 ADU exit sensor (S39)

4.11.15 ADU lower cover

4.11.16 ADU upper cover assembly

4.11.17 Cover interlock switch (SW2)

4.12 Removal and Installation of Options

4.12.1 MR-3021/3022 (Reversing Automatic Document Feeder (RADF))

4.12.2 KD-1027 (Paper Feed Pedestal (PFP))

4.12.3 KD-1028 (Large Capacity Feeder (LCF))

4.12.4 MJ-1101 (Finisher)

4.12.5 MJ-1106 (Saddle Stitch Finisher)

4.12.6 MJ-1031 (Hanging Finisher)

4.12.7 MJ-6103 (Hole punch unit)

4.12.8 KN-4530 (Bridge unit)

4.12.9 MF-3500 (Damp Heater Kit)

Visit our Toshiba Support for Toshiba printer drivers, guides, manuals, tutorials, troubleshooting help and more for our line-up of MFPs, office printers, office copiers, thermal barcode printers and more.

5. SELF-DIAGNOSTIC MODE

5.1 Overview

5.2 Service UI

5.2.1 Overview

5.2.2 Login procedure

5.2.3 [SERVICE MODE] Screen

5.2.4 Setting/Changing password

5.3 Input check (Test mode 03)

5.4 Output check (test mode 03)

5.5 Test print mode (test mode 04)

5.6 Operation Procedure in Adjustment Mode (05)

5.7 Test print pattern in Adjustment Mode (05)

5.8 Operation Procedure in Setting Mode (08)

5.9 Assist Mode (3C)

5.9.1 Assist Mode

5.9.2 Operating Procedure

5.10 HDD Assist Mode (4C)

5.10.1 General description

5.10.2 Operation procedure

5.10.3 Functions

5.11 File System Recovery Mode (5C)

5.11.1 Overview

5.11.2 Operation procedure

5.11.3 Functions

5.12 SRAM Clear Mode (6C)

5.12.1 General description

5.12.2 Operation procedure

5.12.3 Functions

5.13 List print mode (9S)

5.13.1 Operation procedure

5.13.2 List Printing

5.14 Pixel counter

5.14.1 Outline

5.15 Default setting / restore setting of the EFI Printer Board

https://serviceyellow196.weebly.com/orange-juice-font-download-for-mac.html. This font package contains 1 font files.

Toshiba E Studio 2040c User Manual Free

6. SETTING / ADJUSTMENT

6.1 Image Related Adjustment

6.1.1 Adjustment Order

6.1.2 Adjustment of the Auto-Toner Sensor

6.1.3 Performing Image Quality Control

6.1.4 Adjustment of Color Registration Control

6.1.5 Adjustment of the transfer belt due to environmental factors

6.1.6 Image Dimensional Adjustment

6.1.7 Paper alignment at the registration roller

6.1.8 Image dimensional adjustment at the printing section

6.1.9 Image dimensional adjustment at the scanning section

6.2 Image Quality Adjustment (Copying Function)

6.2.1 Automatic gamma adjustment

6.2.2 Density adjustment

6.2.3 Color balance adjustment

6.2.4 Gamma balance adjustment

6.2.5 Background adjustment

6.2.6 Judgment threshold for ACS (common for copy and scan)

6.2.7 Sharpness adjustment

6.2.8 Setting range correction

6.2.9 Adjustment of smudged/faint text

6.2.10 Color Adjustment of Marker

6.2.11 Beam level conversion setting

6.2.12 Maximum toner density adjustment to paper type

6.2.13 Maximum text density adjustment

6.2.14 Text/Photo reproduction level adjustment

6.2.15 Black header density level adjustment

6.2.16 Black area adjustment in twin color copy mode

6.2.17 Judgment threshold adjustment for blank originals

6.2.18 Background offsetting adjustment for RADF

6.2.19 Twin color copy / mono color copy adjustment

6.2.20 Maximum density adjustment for each paper type

6.3 Image Quality Adjustment (Printing Function)

6.3.1 Automatic gamma adjustment

6.3.2 Gamma balance adjustment (Black Mode)

6.3.3 Color balance adjustment

6.3.4 Adjustment of faint text

6.3.5 Upper limit value at Toner Saving Mode

6.3.6 Maximum toner density adjustment (OHP)

6.3.7 Fine line enhancement switchover

6.3.8 “PureBlack/PureGray” threshold adjustment (PCL)

6.3.9 “PureBlack/PureGray” threshold adjustment (Twin color mode)

6.3.10 “PureBlack/PureGray” threshold adjustment (PS)

6.3.11 “PureBlack/PureGray” threshold adjustment (XPS)

6.3.12 Toner limit threshold adjustment

6.3.13 Screen switchover

6.3.14 Sharpness adjustment

6.3.15 Thin line width lower limit adjustment

6.3.16 Offsetting adjustment for background processing

6.3.17 Color/black judgment setting for twin color printing images

6.3.18 Beam level conversion setting

6.4 Image Quality Adjustment (Scanning Function)

6.4.1 Gamma balance adjustment

6.4.2 Density adjustment

6.4.3 Background adjustment (Color Mode)

6.4.4 Judgment threshold for ACS (common for copy and network scan)

6.4.5 Sharpness adjustment

6.4.6 Setting range correction

6.4.7 Fine adjustment of black density

6.4.8 RGB conversion method selection

6.4.9 Adjustment of saturation

6.4.10 Background processing offset adjustment

6.4.11 Adjustment of the capacity and image quality of SlimPDF

6.4.12 Surrounding void amount adjustment

6.5 Image Quality Adjustment (FAX Function)

6.5.1 Density adjustment

6.5.2 Beam level conversion setting

6.6 Scanner

6.6.1 Adjustment carriages-1 and -2 positions

6.6.2 Belt tension adjustment of the Scan motor

6.7 Laser Optical Unit

6.7.1 Image Adjustment in Laser Optical Unit

6.8 Paper Feeding System

6.8.1 Sheet sideways deviation caused by paper feeding

6.8.2 Adjusting the clearance of the paper and side guides

6.9 Process Unit Related Section

6.9.1 High-Voltage Transformer Setting

6.10 Developer Unit

6.10.1 Adjustment of the Auto-Toner Sensor

6.10.2 Adjustment of the doctor-to-sleeve gap

6.11 Transfer Unit

6.11.1 Adjustment of the transfer belt due to environmental factors

6.11.2 Adjustment of Gap between Transfer Belt Unit (TBU) Drive Gears

6.12 Image Quality Control

6.12.1 Performing Image Quality Control

6.13 Fuser Unit / Paper Exit Section

6.13.1 Adjustment of the Separation Plate Gap

Toshiba 2040c Manual

7. PREVENTIVE MAINTENANCE (PM)

7.1 General Description

7.2 PM Display

7.2.1 General Description

7.2.2 PM Display Conditions

7.2.3 PM Display Contents

7.2.4 Counter Clearing

7.3 General Descriptions for PM Procedure

7.4 PM Support Mode

7.4.1 General Description

7.4.2 Operational flow

7.4.3 Operational screen

7.4.4 Access tree

7.5 Work flow of parts replacement

7.6 Preventive Maintenance Checklist

7.6.1 Scanner

7.6.2 Laser unit

7.6.3 Feed unit

7.6.4 Automatic duplexing unit

7.6.5 Bypass feed unit

7.6.6 Main charger

7.6.7 Drum/Cleaner unit, Cleaner related section

7.6.8 Developer unit (K, Y, M, and C)

7.6.9 Waste Toner Box

7.6.10 Transfer belt unit / Transfer belt cleaning unit

7.6.11 Image quality control unit

7.6.12 2nd transfer roller unit

7.6.13 Fuser unit

7.6.14 Exit unit

7.6.15 RADF (MR-3021/3022)

7.6.16 PFP (KD-1027)

7.6.17 LCF (KD-1028)

7.7 Storage of Supplies and Replacement Parts

7.8 PM KIT

7.9 Maintenance Part List

7.10 Grease List

7.11 Operational Items in Overhauling Kubota operators manual download.

8. ERROR CODE AND TROUBLESHOOTING

8.1 General Descriptions

8.1.1 If a problem continues even after performing all troubleshooting

8.1.2 Collection of debug log with USB media

8.2 Error Code List

8.2.1 Jam

8.2.2 Service call

8.2.3 Error in Internet FAX / Scanning Function

8.2.4 Printer function error

8.2.5 TopAccess related error/Communication error with external application

8.2.6 MFP access error

8.2.7 Maintenance error

8.2.8 Network error

8.2.9 Error history

8.3 Diagnosis and Prescription for Each Error Code

8.3.1 Check item

8.3.2 Paper transport jam (paper exit section)

8.3.3 Paper misfeeding

8.3.4 Paper transport jam

8.3.5 Other paper jam

8.3.6 Cover open jam

8.3.7 RADF jam

8.3.8 Jam in bridge unit

8.3.9 Paper jam in finisher section

8.3.10 Paper jam in saddle stitcher section

8.3.11 Paper jam in puncher unit

8.3.12 Other paper jam

8.3.13 Paper feeding system related service call

8.3.14 Scanning system related service call

8.3.15 Fuser unit related service call

8.3.16 Communication related service call

8.3.17 RADF related service call

8.3.18 Circuit related service call

8.3.19 Laser optical unit related service call

8.3.20 Finisher related service call

8.3.21 Image control related service call

8.3.22 Copy process related service call

8.3.23 Other service call

8.3.24 Error in Internet FAX / Scanning Function

8.3.25 Printer function error

8.3.26 TopAccess related error/Communication error with external application

8.3.27 MFP access error

8.3.28 Maintenance error

8.3.29 Network error

8.4 Other errors

8.4.1 Equipment operation disabled after the installation of option(s)

8.4.2 Wireless LAN connection disabled

8.4.3 “Start page” printing disabled after the installation of the EFI Printer Board

(GA-1211, optional)

8.4.4 “Invalid Department Code” is displayed

8.4.5 Paper folded on the leading edge

8.4.6 Abnormality of Recovery from the Sleep Mode (poor fusing, toner offset or

delay of print start in the color mode)

8.4.7 Toner cartridge unrecognized

8.4.8 Error code “M00” is displayed while updating firmware

8.4.9 “Authentication Failed” is displayed

8.5 Troubleshooting for the Image

8.5.1 Color deviation

8.5.2 Uneven pitch and jitter image

8.5.3 Poor image density, color reproduction and gray balance

8.5.4 Background fogging

8.5.5 Moire /lack of sharpness

8.5.6 Toner offset

8.5.7 Blurred image

8.5.8 Poor fusing

8.5.9 Blank print

8.5.10 Solid print

8.5.11 White banding (in feeding direction)

8.5.12 White banding (at right angles to feeding direction)

8.5.13 Skew (slantwise copying)

8.5.14 Color banding (in feeding direction)

8.5.15 Color banding (at right angles to feeding direction)

8.5.16 White spots

8.5.17 Poor transfer

8.5.18 Uneven image density 1 (in feeding direction)

8.5.19 Uneven image density 1 (at right angles to feeding direction)

8.5.20 Uneven image density 2

8.5.21 Faded image (low density)

8.5.22 Image dislocation in feeding direction

8.5.23 Image jittering

8.5.24 Poor cleaning

8.5.25 Uneven light distribution

8.5.26 Blotched image

8.5.27 Stain on the paper back side

8.5.28 White void in the halftone

8.5.29 Paper wrinkle

8.5.30 White void in the halftone

8.5.31 Faint image (immediately after equipment installation)

8.5.32 Tilted image at the leading edge of paper

9. REPLACEMENT OF PC BOARDS/HDD

9.1 Removal and Installation of PC Boards/HDD

9.1.1 Hard disk (HDD)

9.1.2 Board cover

9.1.3 FAX cover

9.1.4 SYS/HDD cooling fan

9.1.5 SYS board

9.1.6 IMG board

9.1.7 LGC board

9.1.8 Switching regulator

9.1.9 High-voltage transformer (HVT)

9.1.10 FIL board

9.1.11 Board case

9.1.12 SRAM board

9.1.13 SRAM board

9.2 Precautions, Procedures and Settings for Replacing PC Boards and HDD

9.2.1 Precautions when replacing PC boards

9.2.2 HDD fault diagnosis

9.2.3 Precautions and procedures when replacing the HDD

9.2.4 Precautions and Procedures when replacing the SYS board

9.2.5 Procedures and settings when replacing the SLG board

9.2.6 Precautions and procedure when replacing the SRAM board

(for the SYS board)

9.2.7 Procedures and settings when replacing SRAM board (for LGC board)

9.2.8 Firmware confirmation after the PC board/HDD replacement

9.2.9 License re-registration using the one-time dongle

9.3 Precautions for Installation of GP-1070 and Disposal of HDD/Board

9.3.1 Precautions for Installation of GP-1070

9.3.2 Precautions when disposing of the HDD

9.3.3 Precautions when disposing of the SYS board

9.3.4 Precautions when disposing of the SRAM board (for SYS board)

9.3.5 Precautions when disposing of the SRAM board (for LGC board)

Tekken 3 Full maintains the same core fighting system and concept as its predecessors, but it brings a lot of improvements, such as significantly more detailed graphics and animations, fifteen new addition to the list of game characters, the latest music, and the fastest game more fluid. Followed by the successor of Canon Tekken 4 in the arcade and PlayStation 2 in 2001 and 2002 respectively. Perhaps the most famous battle system changes Tekken 2 is the reform movement – while the element of depth is rather insignificant in previous Tekken games (except for some characters have unique sidesteps and dodging maneuvers), Tekken 3, showcasing the third axis, so all signs to avoid or leave the fund easy to press arcade stick (or press control console version) in the corresponding direction. Tekken 3 for pc free download. What another significant change in motion is jumping is softer, not allowing fighters to jump to extreme heights (which was present in previous games), but keep climbing sensible realistic heights.

10. REMOTE SERVICE

10.1 Auto Supply Order

10.1.1 Outline

10.1.2 Setting Item

10.1.3 Setting procedure

10.1.4 Order Sheet Format

10.2 Service Notification

10.2.1 Outline

10.2.2 Setting

10.2.3 Items to be notified

11. FIRMWARE UPDATING

11.1 Firmware Updating with USB Media

11.1.1 Master data/System ROM/Engine ROM/Scanner ROM / RADF ROM

11.2 Patch Updating with USB Media

11.2.1 Master data/System ROM

11.3 Firmware Updating with PWA-DWNLD-350-JIG1

11.3.1 Writing the data to the download jig (PWA-DWNLD-350-JIG1)

11.3.2 System ROM

11.3.3 Engine ROM

11.4 Firmware Updating with K-PWA-DLM-320

11.4.1 Scanner ROM

11.4.2 RADF firmware (MR-3021/3022)

11.4.3 Finisher firmware (MJ-1031)

11.4.4 Finisher firmware (MJ-1101)

11.4.5 Finisher firmware (MJ-1106)

11.4.6 Converter Firmware (MJ-1101)

11.4.7 Converter Firmware (MJ-1106)

11.4.8 Saddle stitcher firmware (MJ-1106)

11.4.9 Hole punch unit firmware (MJ-6103)

11.4.10 Fax unit firmware (GD-1250)

11.5 Confirmation of the updated data

11.6 When Firmware Updating Fails

11.6.1 Procedure

11.6.2 Flow chart for correcting USB update failure

12. BACKUP FUNCTION

12.1 Data Cloning

12.1.1 General description

12.1.2 Precautions

12.1.3 Backup files

12.1.4 Cloning procedure

12.2 AES Data Encryption Function Setting

12.2.1 General description

12.2.2 Precautions

12.2.3 Setting procedure

12.2.4 Procedure for disabling data encryption function

12.2.5 Procedure for discarding HDD when data encryption function is enabled

12.3 High Security Mode

12.3.1 General description

12.3.2 Prior confirmation

12.3.3 Procedure for entering the High Security Mode

12.3.4 Precautions

13. EXTERNAL COUNTERS

13.1 Outline

13.2 Signal

13.2.1 Pin Layout

13.2.2 Details of the signals

13.3 Notices

13.3.1 Setting code

13.3.2 Setting value change and restrictions when using the Card Controller

13.3.3 Setting value change and restrictions when using the coin controller

13.3.4 Setting value change and restrictions when using the key counter

13.3.5 Installation of External Counter

14. WIRE HARNESS CONNECTION

14.1 AC Wire Harness

14.2 DC Wire Harness / Electric Parts Layout

15. SELF-DIAGNOSIS CODE (03/04/05/08 CODE)

Input check (test mode 03)

Output check (test mode 03)

Test print mode (test mode 04)

Adjustment Mode (05) Codes

Setting Mode (08) Codes

Toshiba 2040c Brochure

_____________________

Content for Parts List Manual:

COVER-1-ASY

COVER-2-ASY

CONTROL-PANEL-ASY

BASE-FRAME-ASY

FRONT-FRAME-ASY

REAR-FRAME-ASY-1

REAR-FRAME-ASY-2

POWER-SUPPLY-ASY

CASE-PCB-ASY

COV_STAY-PCB-ASY

LASER-OPTICAL-UNIT

OPTICAL-FRAME-ASY

TRU-UNIT-1

TRU-UNIT-2

DEV_TBU-DRIVE-ASY

DRUM-DRIVE-ASY

REGIST&TR1-DRIVE-ASY

FUSER&EXIT-DRIVE-ASY

OPTICAL-DRIVE-ASY

FEEDER-1-ASY

FEEDER-2-ASY

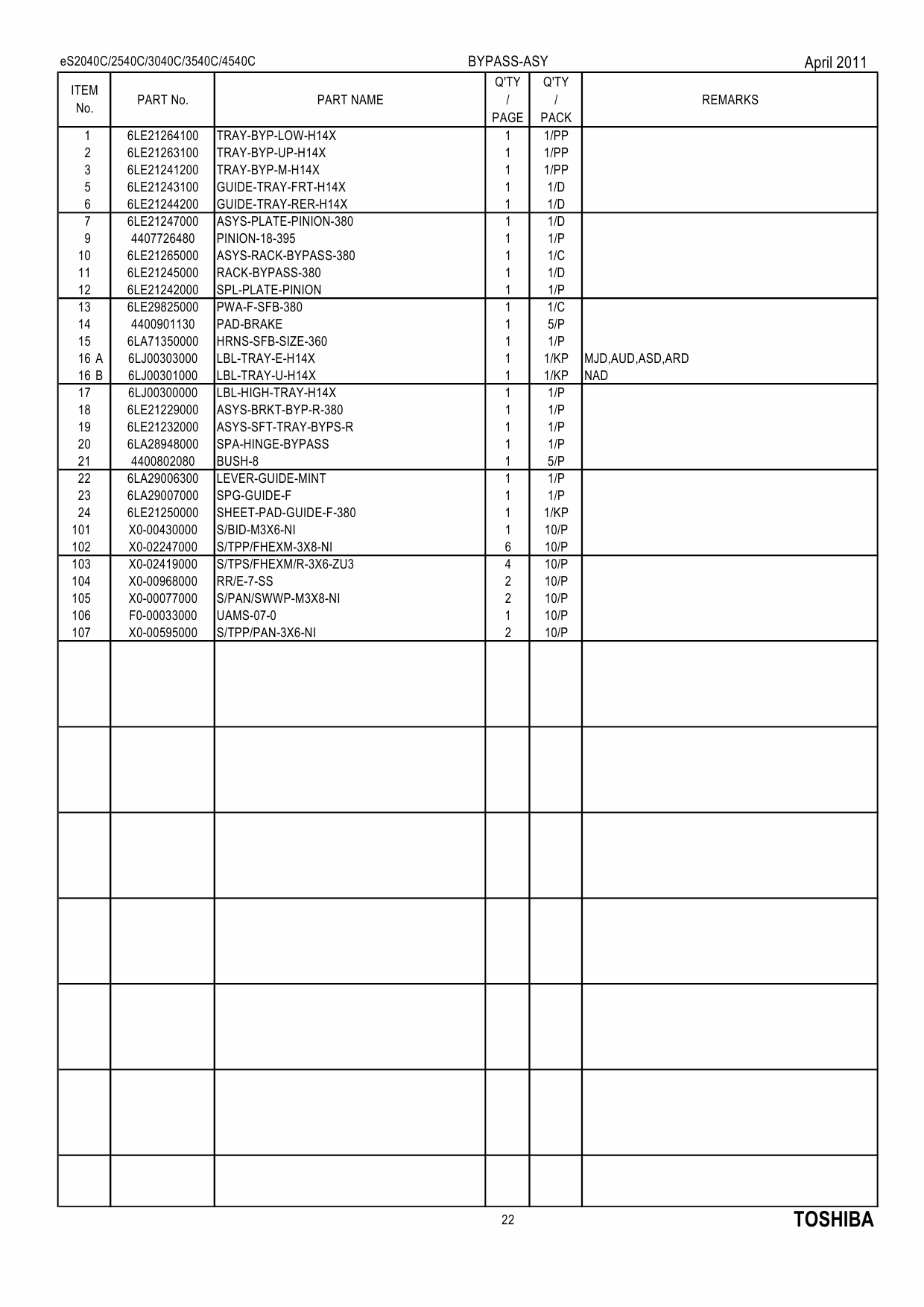

BYPASS-ASY

BYPASS-FEEDER-1-ASY

BYPASS-FEEDER-2-ASY

ALIGNING-ASY

COV&GUIDE-FEED-ASY

LIFT-TRU&SNR-POS-ASY

PLATEN-ASY

CRG-1-ASY

CRG-2-ASY

TRANSPORT-BELT-UNIT-1

TRANSPORT-BELT-UNIT-2

TRANSPORT-BELT-UNIT-3

TRANSPORT-BELT-UNIT-4

BELT-CLEAN-UNIT-ASY

SHUTTER-ASY

EPU-SUB-ASY

DEVELOPER-ASY

CLN-DRUM-ASY

MAIN-CHARGER-ASY

TONER-1-ASY

TONER-2-ASY

FUSER-1-ASY

FUSER-2-ASY

FUSER-3-ASY

FUSER SATY&GUIDE EXIT-ASY

INNER-COVER-ASY

ADU-ASY-1

ADU-ASY-2

DRAWER-ASY

JIGS & GREASE

DOWNLOAD JIGS

SUPPLIES

REPLACE UNIT

PM-KIT

Number of pages: 1616.

e-STUDIO 2040C 2540C 3040C 3540C 4540C e-STUDIO2040C e-STUDIO2540C e-STUDIO3040C e-STUDIO3540C e-STUDIO4540C et2040C et2540C et3040C et3540C et4540C et-2040C et-2540C et-3040C et-3540C et-4540C

Service Manual and Parts List Manual Toshiba e-STUDIO 2040C/2540C/3040C/3540C/4540C (Version 05 F, Oct. https://greatswiss522.weebly.com/movavi-video-converter-17-serial-key-por-mega.html. 2013);

This manual is in the PDF format and have detailed Diagrams, pictures and full procedures to diagnose and repair your Toshiba e-STUDIO copier.

You can print, zoom or read any diagram, picture or page from this Service Manual and Parts List Manual. Every chapter on this manual is fully detailed and contain all the simulation codes, trouble codes, maintenance procedures, reset procedures, diagnose procedures of Toshiba e-STUDIO 2040C/2540C/3040C/3540C/4540C photocopier. You can find easily everything what do you need.

To see what contain, please read table of contents:

Content for Service Manual:

1. FEATURE

1.1 Main Feature of e-STUDIO2040C/2540C/3040C/3540C/4540C

2. SPECIFICATIONS/ACCESSORIES/OPTIONS/SUPPLIES

2.1 Specifications

2.1.1 General

2.1.2 Copy

2.1.3 Print

2.1.4 Scan

2.1.5 e-Filing

2.1.6 Internet Fax

2.1.7 Network Fax

2.2 Accessories

2.3 System List

2.4 Supplies

3. OUTLINE OF THE MACHINE

3.1 Sectional View

3.1.1 Front side-1

3.1.2 Front side-2

3.1.3 Rear side

3.2 Electric Parts Layout

3.3 Symbols and Functions of Various Components

3.3.1 Motors

3.3.2 Sensors and switches

3.3.3 Electromagnetic spring clutches

3.3.4 Solenoids

3.3.5 PC boards

3.3.6 Lamps and heaters

3.3.7 Thermistors, thermopiles, and thermostats

3.3.8 Transformer

3.3.9 Others

3.4 Copy Process

3.5 Comparison with e-STUDIO2020C/2330C/2820C/2830C/3520C/3530C/4520C

3.6 General Operation

3.6.1 Overview of Operation

3.6.2 Description of Operation

3.6.3 Detection of Abnormality

3.7 Control Panel

3.7.1 General Description

3.7.2 Description of Operation

3.8 Scanner

3.8.1 General Description

3.8.2 Construction

3.8.3 Functions

3.8.4 Description of Operation

3.8.5 Process of detection of original size

3.9 Laser Optical Unit

3.9.1 General Description

3.9.2 Laser Precautions

3.10 Paper Feeding System

3.10.1 General Descriptions

3.10.2 Composition

3.10.3 Functions

3.10.4 Description of Operation

3.11 Process Unit Related Section

3.11.1 General description

3.11.2 Composition

3.11.3 Functions

3.11.4 Drum driving sleep mode

3.11.5 Description of Operation

3.12 Developer Unit

3.12.1 General Description

3.12.2 Composition

3.12.3 Functions

3.12.4 Functions of the toner cartridge PC board (CTRG)

3.13 Transfer Unit

3.13.1 General Descriptions

3.13.2 Composition

3.13.3 Difference of transfer belt unit

3.13.4 Contacting and releasing movement of the 2nd transfer roller

3.14 Image Quality Control

3.14.1 General Description

3.15 Fuser unit / Paper exit section

3.15.1 General Description

3.15.2 Composition

3.15.3 Difference of fuser unit

3.15.4 Electric Circuit Description

3.16 Automatic Duplexing Unit (ADU)

3.16.1 General Description

3.16.2 Composition

3.16.3 Drive of ADU

3.16.4 Description of Operations

3.17 Power Supply Unit

3.17.1 General description

3.17.2 Functions

3.17.3 Operation of DC Output Circuits

3.17.4 Output Channel

3.17.5 Fuse Krusty krab pizza song download.

4. DISASSEMBLY AND REPLACEMENT

4.1 Covers

4.1.1 Front cover

4.1.2 Inner tray

4.1.3 Tray back cover

4.1.4 Front upper cover

4.1.5 Front right cover

4.1.6 Left upper cover

4.1.7 Left cover

4.1.8 Left lower cover

4.1.9 Left rear cover

4.1.10 Right upper cover

4.1.11 Right rear cover

4.1.12 Right rear hinge cover

4.1.13 Right lower cover

4.1.14 Right front hinge cover

4.1.15 Bypass rear cover

4.1.16 Right inner cover

4.1.17 Upper rear cover

4.1.18 Rear cover-1

4.1.19 Rear cover-2

4.1.20 Rear cover-3

4.1.21 Waste toner cover

4.2 Control Panel

4.2.1 Stopper

4.2.2 Control panel unit

4.2.3 DSP board

4.2.4 KEY board

4.2.5 Touch panel (TCP)

4.2.6 Control panel cover

4.3 Scanner

4.3.1 Original glass

4.3.2 Lens cover

4.3.3 Automatic original detection sensor (APS sensor)

4.3.4 Exposure lamp (EXP)

4.3.5 Lens unit

4.3.6 Scan motor (M1)

4.3.7 Carriage-1

4.3.8 Inverter board (INV)

4.3.9 Carriage wire / carriage-2

4.3.10 Carriage home position sensor (S6)

4.3.11 Platen sensor (S7)

4.3.12 SLG board (SLG)

4.3.13 Scanner unit cooling fan (M30)

4.3.14 Exposure lamp cooling fan (M32)

4.4 Laser Optical Unit

4.4.1 Laser optical unit

4.4.2 Shutter unit

4.4.3 Shutter motor (M12)

4.4.4 Shutter status detection sensor (S20)

4.4.5 Slit glass cleaning pad

4.4.6 Polygonal motor

4.5 Paper Feeding System

4.5.1 Bypass unit

4.5.2 Hinge assembly

4.5.3 SFB board (SFB)

4.5.4 Bypass feed upper cover

4.5.5 Bypass upper guide

4.5.6 Bypass pickup solenoid (SOL1)

4.5.7 Bypass paper sensor (S40)

4.5.8 Bypass pickup roller

4.5.9 Bypass feed roller

4.5.10 Bypass transport roller

4.5.11 Bypass feed clutch (CLT8)

4.5.12 Bypass separation roller

4.5.13 Bypass feed sensor (S41)

4.5.14 Drawer feeding unit

4.5.15 Tray-up sensor (S31/S35) / Empty sensor (S32/S36)

4.5.16 Paper stock sensor (S33/S37)

4.5.17 Separation roller

4.5.18 Feed roller

4.5.19 Pickup roller

4.5.20 Drawer feed clutch (CLT3/CLT6)

4.5.21 Tray-up motor (M21)

4.5.22 Tray drive unit

4.5.23 2nd drawer transport clutch (Low speed) (CLT4)

4.5.24 2nd drawer transport clutch (High speed) (CLT5)

4.5.25 1st drawer detection switch (SW5) / 2nd drawer detection switch (SW6)

4.5.26 Paper feed guide assembly

4.5.27 2nd drawer feed sensor (S34)

4.5.28 Side cover switch (SW4)

4.5.29 Registration guide

4.5.30 Registration sensor (S28)

4.5.31 1st drawer feed sensor (S30)

4.5.32 Registration roller (Rubber)

4.5.33 Registration motor unit

4.5.34 Registration motor (M19)

4.5.35 Registration roller (Metal)

4.5.36 Paper dust holder

4.5.37 1st drawer transport clutch (Low speed) (CLT2)

4.5.38 Feed/transport motor (M20)

4.5.39 Feed/transport gear unit

4.5.40 1st drawer transport clutch (High speed) (CLT1)

4.5.41 1st drawer transport roller

4.5.42 2nd drawer transport roller

4.6 Process Unit Related Section

4.6.1 Process unit (EPU)

4.6.2 Process cover

4.6.3 Cleaning unit/ Developer unit

4.6.4 Main charger assembly

4.6.5 Main charger cleaner

4.6.6 Main charger grid

4.6.7 Needle electrode

4.6.8 Drum

4.6.9 Drum cleaning blade

4.6.10 Drum thermistor (THM1, THM2)

4.6.11 Discharge LED (ERS-Y, ERS-M, ERS-C, ERS-K)

4.6.12 Needle electrode cleaner detection sensor (S21)

4.6.13 Drum drive unit

4.6.14 Drum motor (M10)

4.6.15 Drum switching motor (M11)

4.6.16 Drum switching detection sensor (S19)

4.6.17 K drum phase sensor (S44)

4.6.18 Color drum phase sensor (S43)

4.7 Developer Unit

4.7.1 Waste toner box

4.7.2 Developer filter

4.7.3 Developer material

4.7.4 Doctor blade

4.7.5 Auto-toner sensor (S22, S23, S24, S25)

4.7.6 Developer sleeve

4.7.7 Mixer

4.7.8 Waste toner transport motor (M31)

4.7.9 Temperature / humidity sensor (S12)

4.7.10 Waste toner box full detection sensor (S13)

4.7.11 Waste toner paddle motor lock detection sensor (S14)

4.7.12 Waste toner paddle motor (M6)

4.7.13 Waste toner transport unit

4.7.14 Waste toner cover open/close detection switch (SW8)

4.7.15 Auger lock detection sensor (S42)

4.7.16 Developer unit motor (M9)

4.7.17 Developer drive unit

4.7.18 Toner motor assembly

4.7.19 Toner motor (M2, M3, M4, M5)

4.7.20 Toner cartridge detection sensor (S8, S9, S10, S11)

4.7.21 Ozone filter-1

4.7.22 EPU cooling fan (M33)

4.7.23 Ozone exhaust fan (M24)

4.7.24 Internal cooling fan (M23)

4.7.25 Ozone filter-2

4.7.26 Ozone filter-3

4.7.27 Front cover opening/closing switch (SW10)

4.8 Transfer Unit

4.8.1 Transfer belt cleaning unit

4.8.2 Transfer belt cleaning blade / Blade seal

4.8.3 Transfer belt unit (TBU)

4.8.4 Transfer belt

4.8.5 Drive roller

4.8.6 1st transfer roller

4.8.7 2nd transfer facing roller / 2nd transfer facing roller cleaning film

4.8.8 Tension roller

4.8.9 1st transfer roller cam motor (M8)

4.8.10 1st transfer roller status detection sensor (S15)

4.8.11 2nd transfer unit (TRU)

4.8.12 2nd transfer roller

4.8.13 TRU cover

4.8.14 Paper clinging detection sensor (S27)

4.8.15 2nd transfer roller position detection sensor (S29)

4.8.16 Transfer belt motor unit

4.8.17 Transfer cover switch (SW3)

4.9 Image Quality Control

4.9.1 Image quality control unit

4.9.2 Image position aligning sensor (front) (S16)

4.9.3 Image position aligning sensor (rear) (S17)

4.9.4 Image quality sensor (S18)

4.9.5 Sensor shutter solenoid (SOL2)

4.10 Fuser unit / Paper Exit Section

4.10.1 Fuser unit

4.10.2 Front side cover

4.10.3 Rear side cover

4.10.4 Heat roller cover

4.10.5 Pressure roller cover

4.10.6 Transport guide

4.10.7 Separation finger unit / Separation finger

4.10.8 Pressure roller / Pressure roller lamp (LAMP3)

4.10.9 Separation plate / Fuser belt unit / Heater lamp (center / side / sub)

4.10.10 Fuser belt / Heat roller / Fuser belt guide / Fuser roller

4.10.11 Pressure roller thermostat (THMO3)

4.10.12 Pressure roller center thermistor (THM4) / Pressure roller rear thermistor

(THM5)

4.10.13 Fuser belt center thermostat (THMO1)

4.10.14 Fuser belt rear thermostat (THMO2)

4.10.15 Fuser belt front thermistor (THM3)

4.10.16 Exit sensor (S26)

4.10.17 Exit unit

4.10.18 Upper exit roller / Lower exit roller

4.10.19 Fuser belt center thermopile(THMP1) / Fuser belt rear thermopile(THMP2). 4-160

4.10.20 Fuser motor (M17)

4.10.21 Exit section drive unit

4.10.22 Fuser drive unit

4.10.23 Fuser/exit section cooling fan (M25) / Exit motor (M18)

4.11 Automatic Duplexing Unit (ADU)

4.11.1 ADU maintenance position

4.11.2 Automatic Duplexing Unit (ADU)

4.11.3 ADU inside rear cover

4.11.4 ADU opening/closing switch (SW7)

4.11.5 ADU board (ADU)

4.11.6 ADU cover

4.11.7 Paper guide

4.11.8 ADU clutch (CLT7)

4.11.9 ADU drive unit / ADU motor (M22)

4.11.10 Upper transport roller

4.11.11 Middle transport roller

4.11.12 Lower transport roller

4.11.13 ADU entrance sensor (S38)

4.11.14 ADU exit sensor (S39)

4.11.15 ADU lower cover

4.11.16 ADU upper cover assembly

4.11.17 Cover interlock switch (SW2)

4.12 Removal and Installation of Options

4.12.1 MR-3021/3022 (Reversing Automatic Document Feeder (RADF))

4.12.2 KD-1027 (Paper Feed Pedestal (PFP))

4.12.3 KD-1028 (Large Capacity Feeder (LCF))

4.12.4 MJ-1101 (Finisher)

4.12.5 MJ-1106 (Saddle Stitch Finisher)

4.12.6 MJ-1031 (Hanging Finisher)

4.12.7 MJ-6103 (Hole punch unit)

4.12.8 KN-4530 (Bridge unit)

4.12.9 MF-3500 (Damp Heater Kit)

Toshiba E Studio 3040c

5. SELF-DIAGNOSTIC MODE

5.1 Overview

5.2 Service UI

5.2.1 Overview

5.2.2 Login procedure

5.2.3 [SERVICE MODE] Screen

5.2.4 Setting/Changing password

5.3 Input check (Test mode 03)

5.4 Output check (test mode 03)

5.5 Test print mode (test mode 04)

5.6 Operation Procedure in Adjustment Mode (05)

5.7 Test print pattern in Adjustment Mode (05)

5.8 Operation Procedure in Setting Mode (08)

5.9 Assist Mode (3C)

5.9.1 Assist Mode

5.9.2 Operating Procedure

5.10 HDD Assist Mode (4C)

5.10.1 General description

5.10.2 Operation procedure

5.10.3 Functions

5.11 File System Recovery Mode (5C)

5.11.1 Overview

5.11.2 Operation procedure

5.11.3 Functions

5.12 SRAM Clear Mode (6C)

5.12.1 General description

5.12.2 Operation procedure

5.12.3 Functions

5.13 List print mode (9S)

5.13.1 Operation procedure

5.13.2 List Printing

5.14 Pixel counter

5.14.1 Outline

5.15 Default setting / restore setting of the EFI Printer Board

6. SETTING / ADJUSTMENT

6.1 Image Related Adjustment

6.1.1 Adjustment Order

6.1.2 Adjustment of the Auto-Toner Sensor

6.1.3 Performing Image Quality Control

6.1.4 Adjustment of Color Registration Control

6.1.5 Adjustment of the transfer belt due to environmental factors

6.1.6 Image Dimensional Adjustment

6.1.7 Paper alignment at the registration roller

6.1.8 Image dimensional adjustment at the printing section

6.1.9 Image dimensional adjustment at the scanning section

6.2 Image Quality Adjustment (Copying Function)

6.2.1 Automatic gamma adjustment

6.2.2 Density adjustment

6.2.3 Color balance adjustment

6.2.4 Gamma balance adjustment

6.2.5 Background adjustment

6.2.6 Judgment threshold for ACS (common for copy and scan)

6.2.7 Sharpness adjustment

6.2.8 Setting range correction

6.2.9 Adjustment of smudged/faint text

6.2.10 Color Adjustment of Marker

6.2.11 Beam level conversion setting

6.2.12 Maximum toner density adjustment to paper type

6.2.13 Maximum text density adjustment

6.2.14 Text/Photo reproduction level adjustment

6.2.15 Black header density level adjustment

6.2.16 Black area adjustment in twin color copy mode

6.2.17 Judgment threshold adjustment for blank originals

6.2.18 Background offsetting adjustment for RADF

6.2.19 Twin color copy / mono color copy adjustment

6.2.20 Maximum density adjustment for each paper type

6.3 Image Quality Adjustment (Printing Function)

6.3.1 Automatic gamma adjustment

6.3.2 Gamma balance adjustment (Black Mode)

6.3.3 Color balance adjustment

6.3.4 Adjustment of faint text

6.3.5 Upper limit value at Toner Saving Mode

6.3.6 Maximum toner density adjustment (OHP)

6.3.7 Fine line enhancement switchover

6.3.8 “PureBlack/PureGray” threshold adjustment (PCL)

6.3.9 “PureBlack/PureGray” threshold adjustment (Twin color mode)

6.3.10 “PureBlack/PureGray” threshold adjustment (PS)

6.3.11 “PureBlack/PureGray” threshold adjustment (XPS)

6.3.12 Toner limit threshold adjustment

6.3.13 Screen switchover

6.3.14 Sharpness adjustment

6.3.15 Thin line width lower limit adjustment

6.3.16 Offsetting adjustment for background processing

6.3.17 Color/black judgment setting for twin color printing images

6.3.18 Beam level conversion setting

6.4 Image Quality Adjustment (Scanning Function)

6.4.1 Gamma balance adjustment

6.4.2 Density adjustment

6.4.3 Background adjustment (Color Mode)

6.4.4 Judgment threshold for ACS (common for copy and network scan)

6.4.5 Sharpness adjustment

6.4.6 Setting range correction

6.4.7 Fine adjustment of black density

6.4.8 RGB conversion method selection

6.4.9 Adjustment of saturation

6.4.10 Background processing offset adjustment

6.4.11 Adjustment of the capacity and image quality of SlimPDF

6.4.12 Surrounding void amount adjustment

6.5 Image Quality Adjustment (FAX Function)

6.5.1 Density adjustment

6.5.2 Beam level conversion setting

6.6 Scanner

6.6.1 Adjustment carriages-1 and -2 positions

6.6.2 Belt tension adjustment of the Scan motor

6.7 Laser Optical Unit

6.7.1 Image Adjustment in Laser Optical Unit

6.8 Paper Feeding System

6.8.1 Sheet sideways deviation caused by paper feeding

6.8.2 Adjusting the clearance of the paper and side guides

6.9 Process Unit Related Section

6.9.1 High-Voltage Transformer Setting

6.10 Developer Unit

6.10.1 Adjustment of the Auto-Toner Sensor

6.10.2 Adjustment of the doctor-to-sleeve gap

6.11 Transfer Unit

6.11.1 Adjustment of the transfer belt due to environmental factors

6.11.2 Adjustment of Gap between Transfer Belt Unit (TBU) Drive Gears

6.12 Image Quality Control

6.12.1 Performing Image Quality Control

6.13 Fuser Unit / Paper Exit Section

6.13.1 Adjustment of the Separation Plate Gap

7. PREVENTIVE MAINTENANCE (PM)

7.1 General Description

7.2 PM Display

7.2.1 General Description

7.2.2 PM Display Conditions

7.2.3 PM Display Contents

7.2.4 Counter Clearing

7.3 General Descriptions for PM Procedure

7.4 PM Support Mode

7.4.1 General Description

7.4.2 Operational flow

7.4.3 Operational screen

7.4.4 Access tree

7.5 Work flow of parts replacement

7.6 Preventive Maintenance Checklist

7.6.1 Scanner

7.6.2 Laser unit

7.6.3 Feed unit

7.6.4 Automatic duplexing unit

7.6.5 Bypass feed unit

7.6.6 Main charger

7.6.7 Drum/Cleaner unit, Cleaner related section

7.6.8 Developer unit (K, Y, M, and C)

7.6.9 Waste Toner Box

7.6.10 Transfer belt unit / Transfer belt cleaning unit

7.6.11 Image quality control unit

7.6.12 2nd transfer roller unit

7.6.13 Fuser unit

7.6.14 Exit unit

7.6.15 RADF (MR-3021/3022)

7.6.16 PFP (KD-1027)

7.6.17 LCF (KD-1028)

7.7 Storage of Supplies and Replacement Parts

7.8 PM KIT

7.9 Maintenance Part List

7.10 Grease List

7.11 Operational Items in Overhauling

Baidu browser free download - Tor Browser, Torch Browser, Adobe Flash Player, and many more programs. Baidu Browser by Baidu Inc. Is a fast and lightweight Internet browser that was originally designed for mobile devices. Even though there is no version of Baidu Browser for Mac available for download, there are plenty other web browsers you can use in its place. The following list contains some alternatives to Baidu Browser for Mac. Baidu browser free download - Baidu Spark Browser, Baidu Antivirus 2015, Baidu Spark Browser for Windows 10, and many more programs. Baidu browser for windows 7. Baidu Browser 2018 (previously Spark Browser) is a blasting quick, free Web program with an instinctive interface and huge amounts of valuable devices worked in. It depends on the Chromium stage, which makes it fast, lightweight and adjustable. Baidu Browser highlights its own particular inherent deluge customer, a media download apparatus for sparing fun recordings and sound to your PC, mouse. Baidu browers free download - Baidu WiFi Hotspot, Baidu Spark Browser, Baidu PC Faster, and many more programs.

8. ERROR CODE AND TROUBLESHOOTING

8.1 General Descriptions

8.1.1 If a problem continues even after performing all troubleshooting

8.1.2 Collection of debug log with USB media

8.2 Error Code List

8.2.1 Jam

8.2.2 Service call

8.2.3 Error in Internet FAX / Scanning Function

8.2.4 Printer function error

8.2.5 TopAccess related error/Communication error with external application

8.2.6 MFP access error

8.2.7 Maintenance error

8.2.8 Network error

8.2.9 Error history

8.3 Diagnosis and Prescription for Each Error Code

8.3.1 Check item

8.3.2 Paper transport jam (paper exit section)

8.3.3 Paper misfeeding

8.3.4 Paper transport jam

8.3.5 Other paper jam

8.3.6 Cover open jam

8.3.7 RADF jam

8.3.8 Jam in bridge unit

8.3.9 Paper jam in finisher section

8.3.10 Paper jam in saddle stitcher section

8.3.11 Paper jam in puncher unit

8.3.12 Other paper jam

8.3.13 Paper feeding system related service call

8.3.14 Scanning system related service call

8.3.15 Fuser unit related service call

8.3.16 Communication related service call

8.3.17 RADF related service call

8.3.18 Circuit related service call

8.3.19 Laser optical unit related service call

8.3.20 Finisher related service call

8.3.21 Image control related service call

8.3.22 Copy process related service call

8.3.23 Other service call

8.3.24 Error in Internet FAX / Scanning Function

8.3.25 Printer function error

8.3.26 TopAccess related error/Communication error with external application

8.3.27 MFP access error

8.3.28 Maintenance error

8.3.29 Network error

8.4 Other errors

8.4.1 Equipment operation disabled after the installation of option(s)

8.4.2 Wireless LAN connection disabled

8.4.3 “Start page” printing disabled after the installation of the EFI Printer Board

(GA-1211, optional)

8.4.4 “Invalid Department Code” is displayed

8.4.5 Paper folded on the leading edge

8.4.6 Abnormality of Recovery from the Sleep Mode (poor fusing, toner offset or

delay of print start in the color mode)

8.4.7 Toner cartridge unrecognized

8.4.8 Error code “M00” is displayed while updating firmware

8.4.9 “Authentication Failed” is displayed

8.5 Troubleshooting for the Image

8.5.1 Color deviation

8.5.2 Uneven pitch and jitter image

8.5.3 Poor image density, color reproduction and gray balance

8.5.4 Background fogging

8.5.5 Moire /lack of sharpness

8.5.6 Toner offset

8.5.7 Blurred image

8.5.8 Poor fusing

8.5.9 Blank print

8.5.10 Solid print

8.5.11 White banding (in feeding direction)

8.5.12 White banding (at right angles to feeding direction)

8.5.13 Skew (slantwise copying)

8.5.14 Color banding (in feeding direction)

8.5.15 Color banding (at right angles to feeding direction)

8.5.16 White spots

8.5.17 Poor transfer

8.5.18 Uneven image density 1 (in feeding direction)

8.5.19 Uneven image density 1 (at right angles to feeding direction)

8.5.20 Uneven image density 2

8.5.21 Faded image (low density)

8.5.22 Image dislocation in feeding direction

8.5.23 Image jittering

8.5.24 Poor cleaning

8.5.25 Uneven light distribution

8.5.26 Blotched image

8.5.27 Stain on the paper back side

8.5.28 White void in the halftone

8.5.29 Paper wrinkle

8.5.30 White void in the halftone

8.5.31 Faint image (immediately after equipment installation)

8.5.32 Tilted image at the leading edge of paper

9. REPLACEMENT OF PC BOARDS/HDD

9.1 Removal and Installation of PC Boards/HDD

9.1.1 Hard disk (HDD)

9.1.2 Board cover

9.1.3 FAX cover

9.1.4 SYS/HDD cooling fan

9.1.5 SYS board

9.1.6 IMG board

9.1.7 LGC board

9.1.8 Switching regulator

9.1.9 High-voltage transformer (HVT)

9.1.10 FIL board

9.1.11 Board case

9.1.12 SRAM board

9.1.13 SRAM board

9.2 Precautions, Procedures and Settings for Replacing PC Boards and HDD

9.2.1 Precautions when replacing PC boards

9.2.2 HDD fault diagnosis

9.2.3 Precautions and procedures when replacing the HDD

9.2.4 Precautions and Procedures when replacing the SYS board

9.2.5 Procedures and settings when replacing the SLG board

9.2.6 Precautions and procedure when replacing the SRAM board

(for the SYS board)

9.2.7 Procedures and settings when replacing SRAM board (for LGC board)

9.2.8 Firmware confirmation after the PC board/HDD replacement

9.2.9 License re-registration using the one-time dongle

9.3 Precautions for Installation of GP-1070 and Disposal of HDD/Board

9.3.1 Precautions for Installation of GP-1070

9.3.2 Precautions when disposing of the HDD

9.3.3 Precautions when disposing of the SYS board

9.3.4 Precautions when disposing of the SRAM board (for SYS board)

9.3.5 Precautions when disposing of the SRAM board (for LGC board)

10. REMOTE SERVICE

10.1 Auto Supply Order

10.1.1 Outline

10.1.2 Setting Item

10.1.3 Setting procedure

10.1.4 Order Sheet Format

10.2 Service Notification

10.2.1 Outline

10.2.2 Setting

10.2.3 Items to be notified

11. FIRMWARE UPDATING

11.1 Firmware Updating with USB Media

11.1.1 Master data/System ROM/Engine ROM/Scanner ROM / RADF ROM

11.2 Patch Updating with USB Media

11.2.1 Master data/System ROM

11.3 Firmware Updating with PWA-DWNLD-350-JIG1

11.3.1 Writing the data to the download jig (PWA-DWNLD-350-JIG1)

11.3.2 System ROM

11.3.3 Engine ROM

11.4 Firmware Updating with K-PWA-DLM-320

11.4.1 Scanner ROM

11.4.2 RADF firmware (MR-3021/3022)

11.4.3 Finisher firmware (MJ-1031)

11.4.4 Finisher firmware (MJ-1101)

11.4.5 Finisher firmware (MJ-1106)

11.4.6 Converter Firmware (MJ-1101)

11.4.7 Converter Firmware (MJ-1106)

11.4.8 Saddle stitcher firmware (MJ-1106)

11.4.9 Hole punch unit firmware (MJ-6103)

11.4.10 Fax unit firmware (GD-1250)

11.5 Confirmation of the updated data

11.6 When Firmware Updating Fails

11.6.1 Procedure

11.6.2 Flow chart for correcting USB update failure

12. BACKUP FUNCTION

12.1 Data Cloning

12.1.1 General description

12.1.2 Precautions

12.1.3 Backup files

12.1.4 Cloning procedure

12.2 AES Data Encryption Function Setting

12.2.1 General description

12.2.2 Precautions

12.2.3 Setting procedure

12.2.4 Procedure for disabling data encryption function

12.2.5 Procedure for discarding HDD when data encryption function is enabled

12.3 High Security Mode

12.3.1 General description

12.3.2 Prior confirmation

12.3.3 Procedure for entering the High Security Mode

12.3.4 Precautions

13. EXTERNAL COUNTERS

13.1 Outline

13.2 Signal

13.2.1 Pin Layout

13.2.2 Details of the signals

13.3 Notices

13.3.1 Setting code

13.3.2 Setting value change and restrictions when using the Card Controller

13.3.3 Setting value change and restrictions when using the coin controller

13.3.4 Setting value change and restrictions when using the key counter

13.3.5 Installation of External Counter

14. WIRE HARNESS CONNECTION

14.1 AC Wire Harness

14.2 DC Wire Harness / Electric Parts Layout

15. SELF-DIAGNOSIS CODE (03/04/05/08 CODE)

Input check (test mode 03)

Output check (test mode 03)

Test print mode (test mode 04)

Adjustment Mode (05) Codes

Setting Mode (08) Codes

_____________________

Ask the question you have about the Panasonic KX-DT543 here simply to other product owners. Provide a clear and comprehensive description of the problem and your question. The better your problem and question is described, the easier it is for other Panasonic KX-DT543 owners to provide you with a good answer. KX-DT521/KX-DT543 /KX-DT546 Digital DSS Console Model No. KX-DT590 Thank you for purchasing a Digital Proprietary Telephone (DPT). Please read this manual carefully before using this product and save this manual for future use. For more details, please refer to the manuals of the PBX. Panasonic KX-DT543 Pdf User Manuals. View online or download Panasonic KX-DT543 Service Manual, Quick Reference Manual, Training Manual, Quick Reference Card. Manual panasonic kx-dt543.

Content for Parts List Manual:

COVER-1-ASY

COVER-2-ASY

CONTROL-PANEL-ASY

BASE-FRAME-ASY

FRONT-FRAME-ASY

REAR-FRAME-ASY-1

REAR-FRAME-ASY-2

POWER-SUPPLY-ASY

CASE-PCB-ASY

COV_STAY-PCB-ASY

LASER-OPTICAL-UNIT

OPTICAL-FRAME-ASY

TRU-UNIT-1

TRU-UNIT-2

DEV_TBU-DRIVE-ASY

DRUM-DRIVE-ASY

REGIST&TR1-DRIVE-ASY

FUSER&EXIT-DRIVE-ASY

OPTICAL-DRIVE-ASY

FEEDER-1-ASY

FEEDER-2-ASY

BYPASS-ASY

BYPASS-FEEDER-1-ASY

BYPASS-FEEDER-2-ASY

ALIGNING-ASY

COV&GUIDE-FEED-ASY

LIFT-TRU&SNR-POS-ASY

PLATEN-ASY

CRG-1-ASY

CRG-2-ASY

TRANSPORT-BELT-UNIT-1

TRANSPORT-BELT-UNIT-2

TRANSPORT-BELT-UNIT-3

TRANSPORT-BELT-UNIT-4

BELT-CLEAN-UNIT-ASY

SHUTTER-ASY

EPU-SUB-ASY

DEVELOPER-ASY

CLN-DRUM-ASY

MAIN-CHARGER-ASY

TONER-1-ASY

TONER-2-ASY

FUSER-1-ASY

FUSER-2-ASY

FUSER-3-ASY

FUSER SATY&GUIDE EXIT-ASY

INNER-COVER-ASY

ADU-ASY-1

ADU-ASY-2

DRAWER-ASY

JIGS & GREASE

DOWNLOAD JIGS

SUPPLIES

REPLACE UNIT

PM-KIT

This product detection tool installs software on your Microsoft Windows device that allows HP to detect and gather data about your HP and Compaq products to provide quick access to support information and solutions. Examples: 'LaserJet Pro P1102 paper jam', 'EliteBook 840 G3 bios update'Need help finding your product name or product number? For Samsung Print products, enter the M/C or Model Code found on the product label. Include keywords along with product name. Examples: “SL-M2020W/XAA”. https://corneparbi.tistory.com/4.

Update adobe reader for mac catalina. Number of pages: 1616.

e-STUDIO 2040C 2540C 3040C 3540C 4540C e-STUDIO2040C e-STUDIO2540C e-STUDIO3040C e-STUDIO3540C e-STUDIO4540C et2040C et2540C et3040C et3540C et4540C et-2040C et-2540C et-3040C et-3540C et-4540C